Stand-Alone vs Hardwired Footswitch Set-ups

Our resistance soldering systems usually consist of a power unit, handpiece and a stand-alone footswitch (10519 or 10519HW). However, on occasion, we hardwire the footswitch directly into the power unit. This tech handout discusses the different 'set-ups' and the benefits and drawbacks of hardwiring the footswitch.

Standard Set-up: Stand-Alone Footswitch

The standard resistance soldering systems consists of a handpiece, power unit and a stand-alone footswitch. The stand-alone footswitch features a piggy-back plug. The proper set-up of the power unit and footswitch has the footswitch plugging into the power outlet and the power unit plugging into the footswitch's piggy-back plug recepticle. Although not recommended, the system can be set-up to operate independently from the footswitch.

Set-up for High Voltage Systems: Hardwired Footswitch

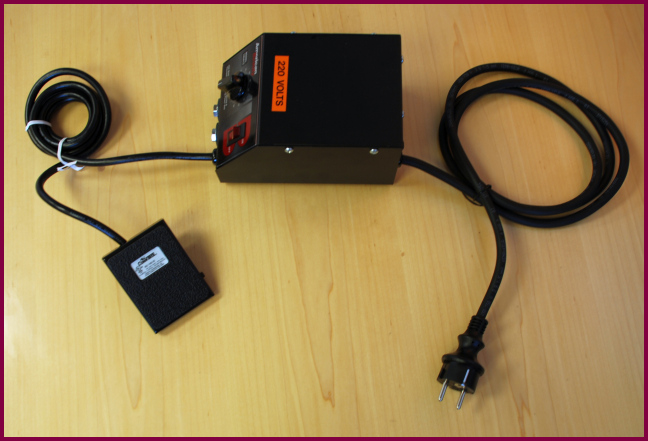

We hardwire the footswitches directly into the power unit when building high voltage versions (220-240 VAC) of our systems. This is done to allow for the customization of these systems with any number of International Cordsets. The photo below features a power unit hardwired with a footswitch and wired with a Continental Europe (aka:Schuko) Cordset (Type A). A possible drawback to this set-up is the inability to bypass the footswitch, in other words, it is always required for operation.

If you are ordering a high voltage resistance soldering systems and DO NOT WANT a hardwired footswtich, you need to specifically request a 'Stand-alone' (-SF) version of the system. This is most commonly ordered with a North American Cordset (NEMA 5-15P) (Type K) and operated with an adapter. (American Beauty Tools does not currently supply any adapters)